Features

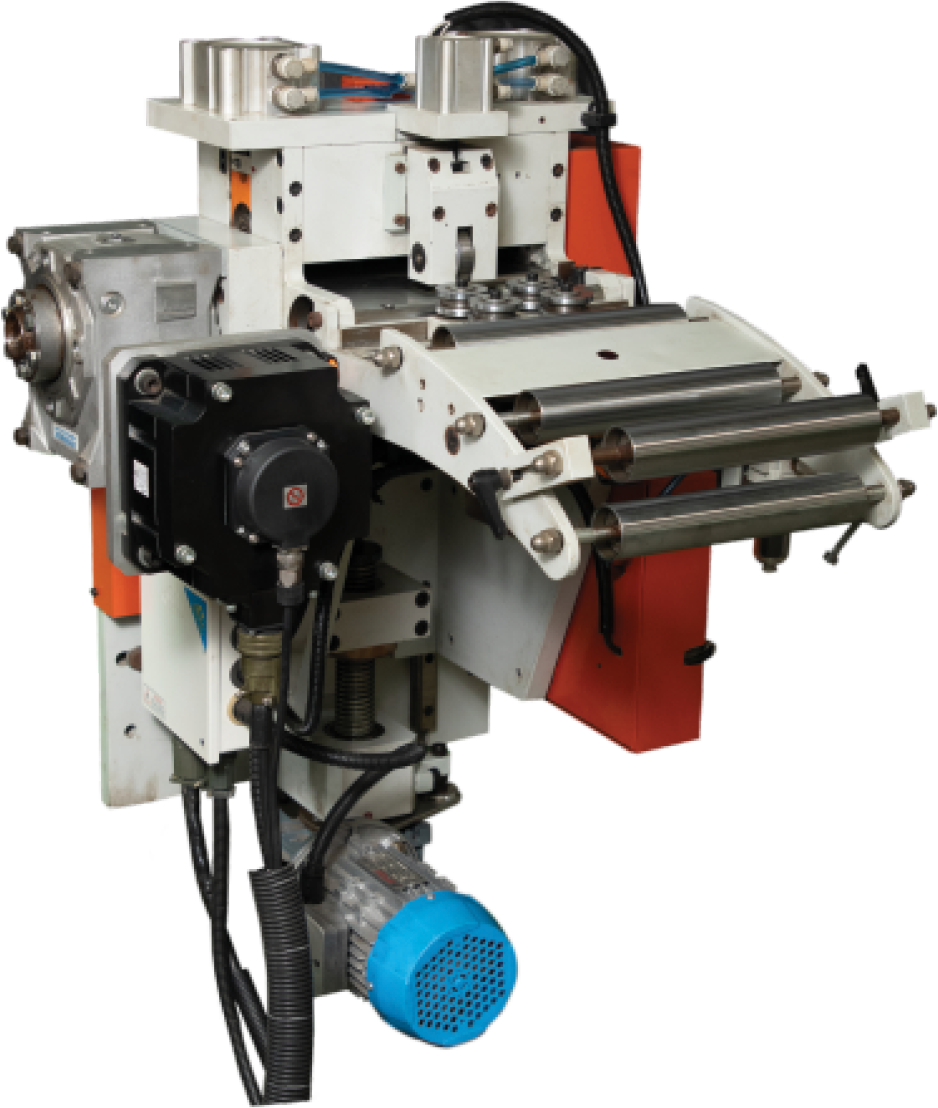

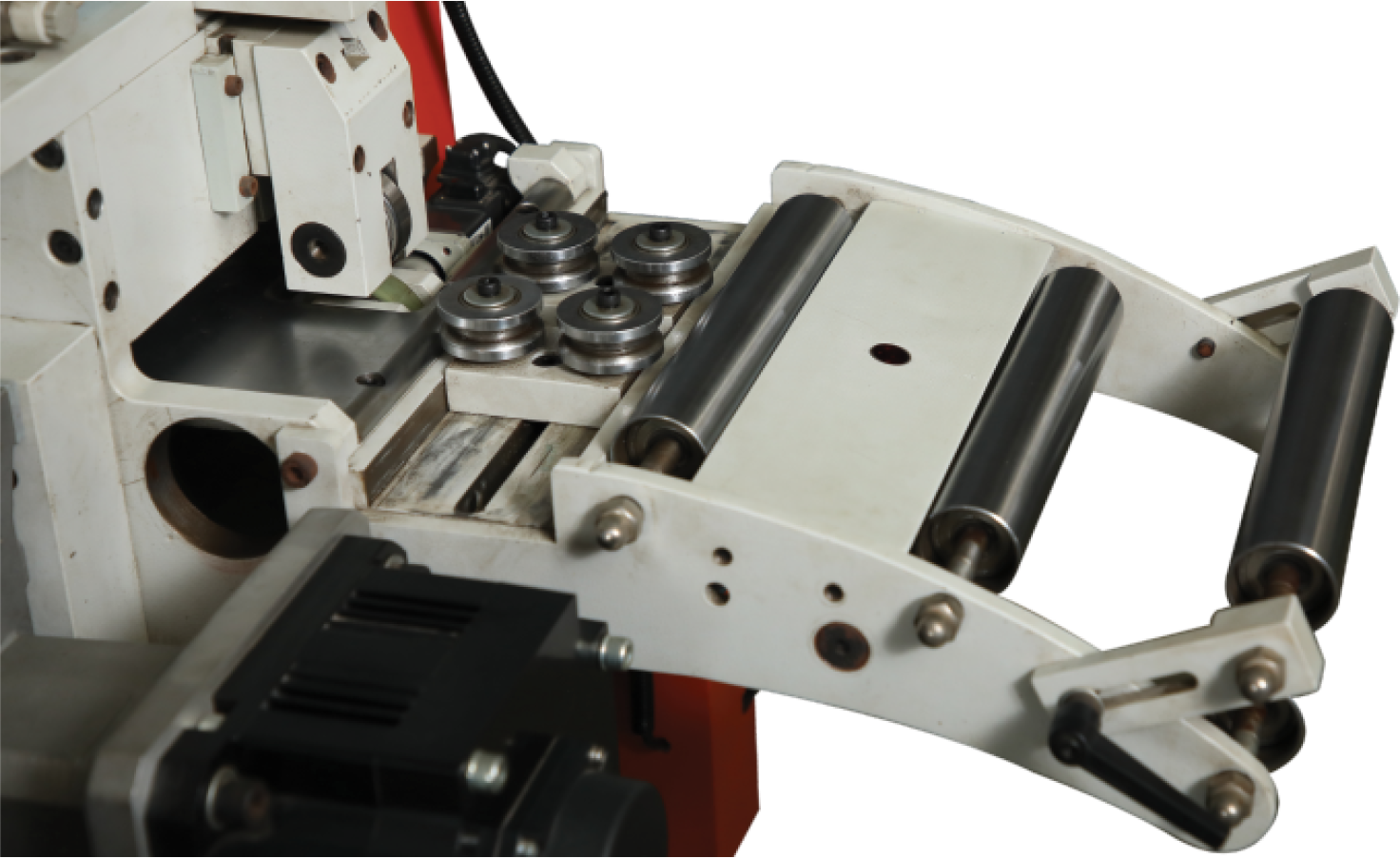

- • The feed rollers are hardened 62 Hrc and ground with a 0.50 micron surface finish.

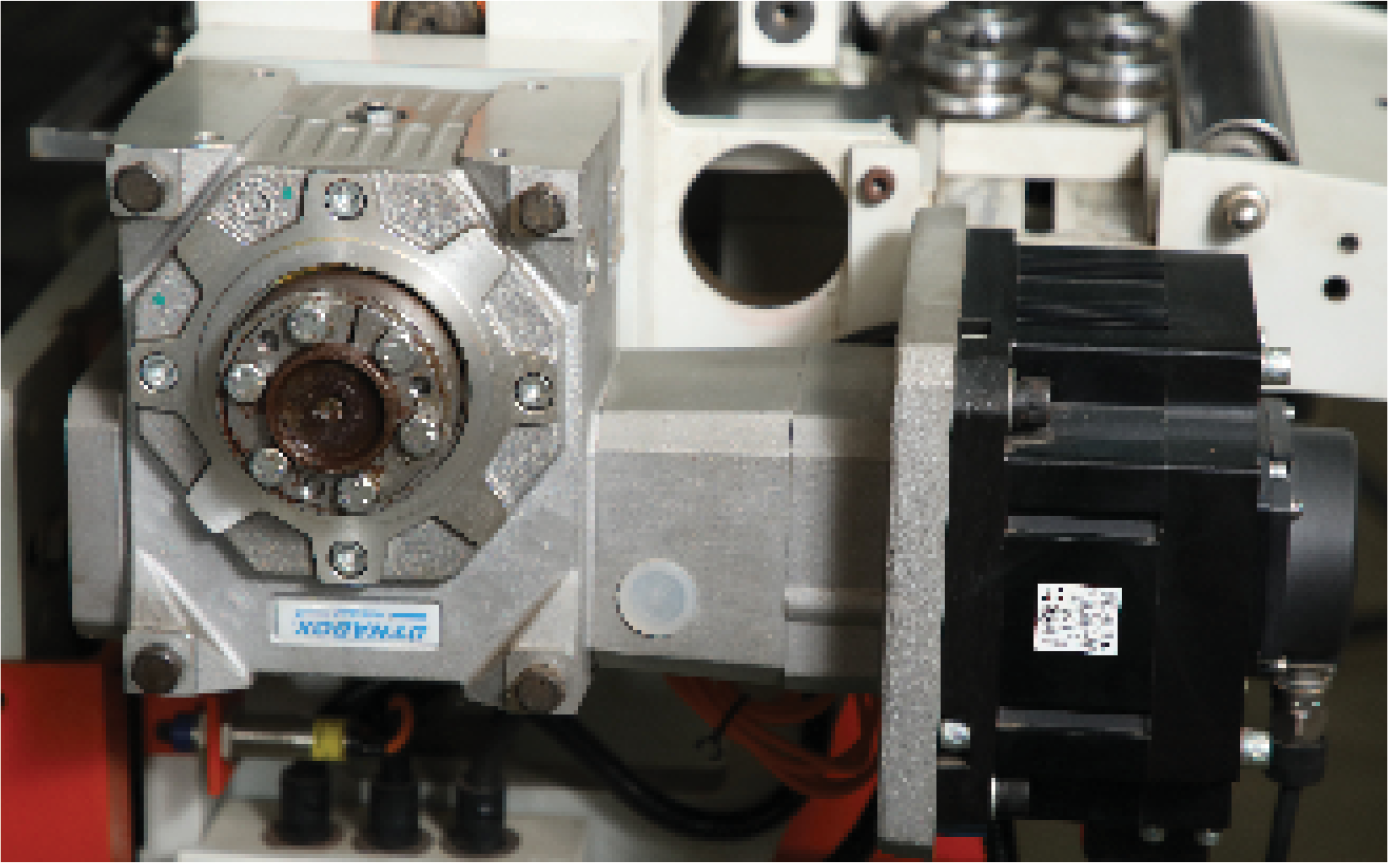

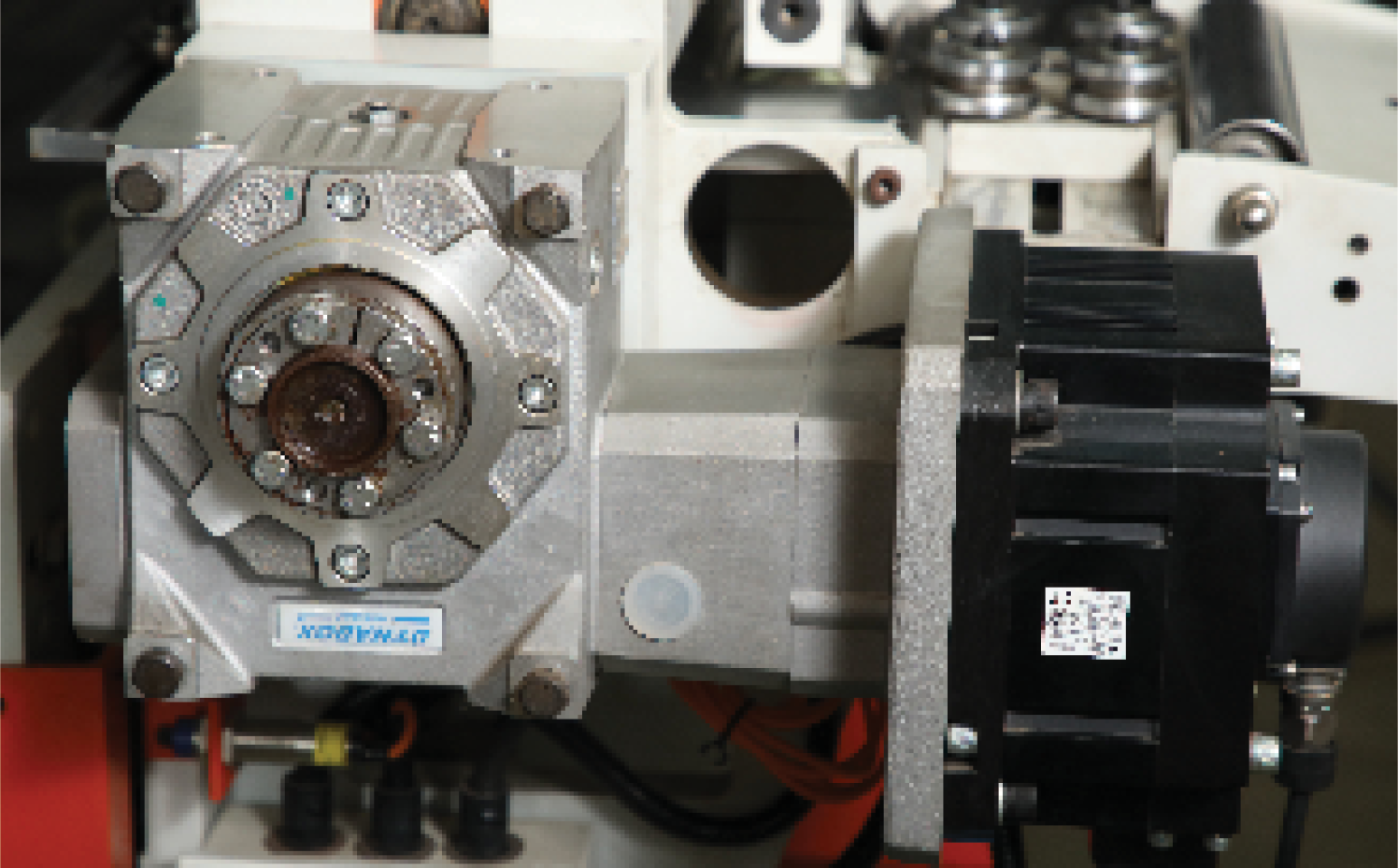

- • The lower roll is directly driven by precision gear box with <5' backlash & brushless servomotor (ratio as per model).

- • Special TDC arrangement for transmission of power from lower shaft to upper shaft which results in min backlash during to / fro motions.

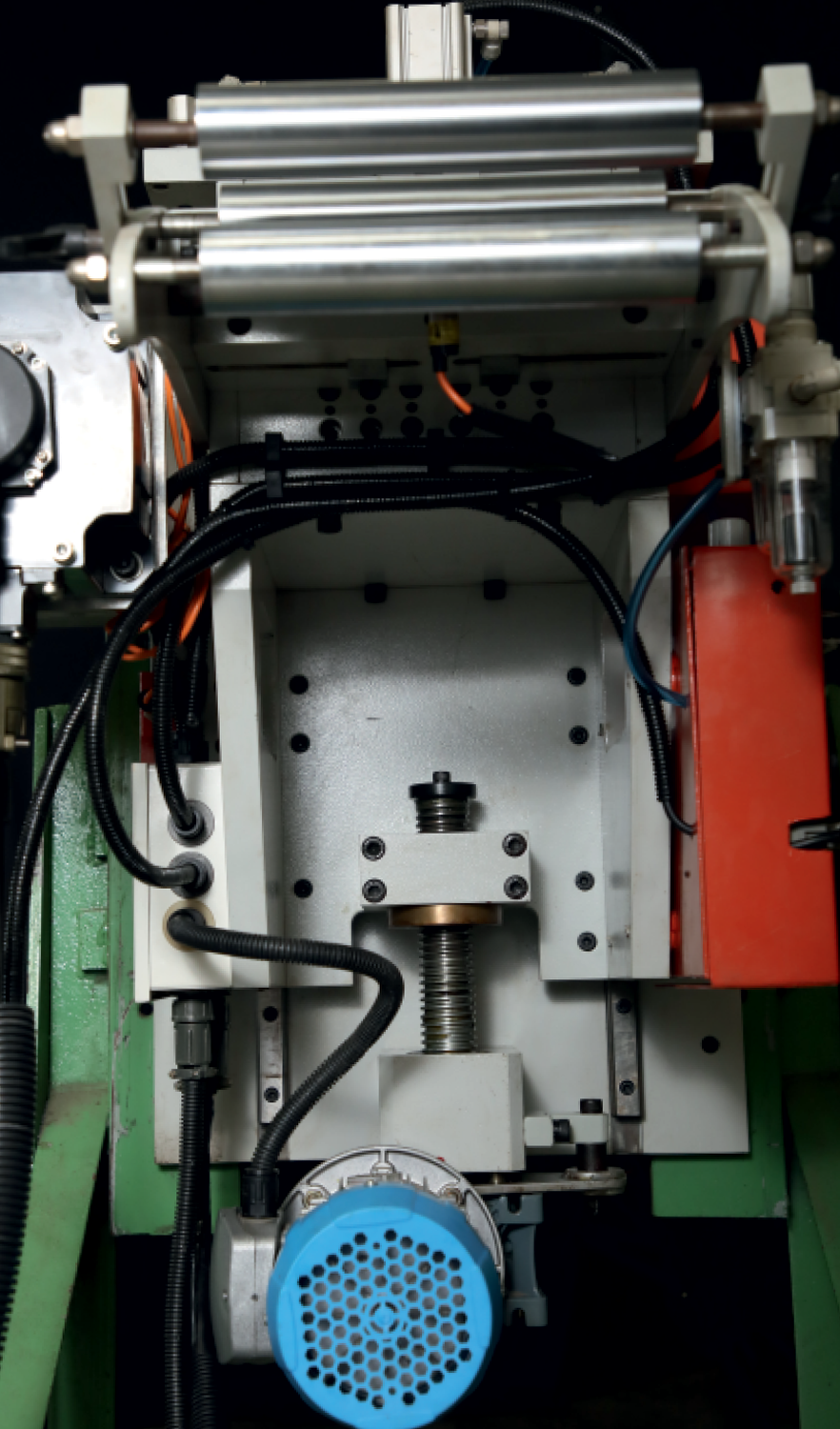

- • Pressure to the upper roller by two pneumatic cylinder with independent pressure release. (SRF 160 via Hydraulic Cylinder)

- • You can open the upper roll at every stroke at 95 -160 spm with angle 50º.

- • The material is positioned in the feeder by 4 guides, these can be used to auto centre the strip together with the ability to adjust the material off centre if required.

- • Inlet bracket roller with 3 lower roll and 1 upper roll.

- • Back Plate with 150 mm of adjustment by manual hydraulic Jack or gear box motor (uptill SRF 100).

- • Support square with 200 mm of adjustment by gear box motor (above SRF 120).

- • Digital servo driver with closed loop positioning system.

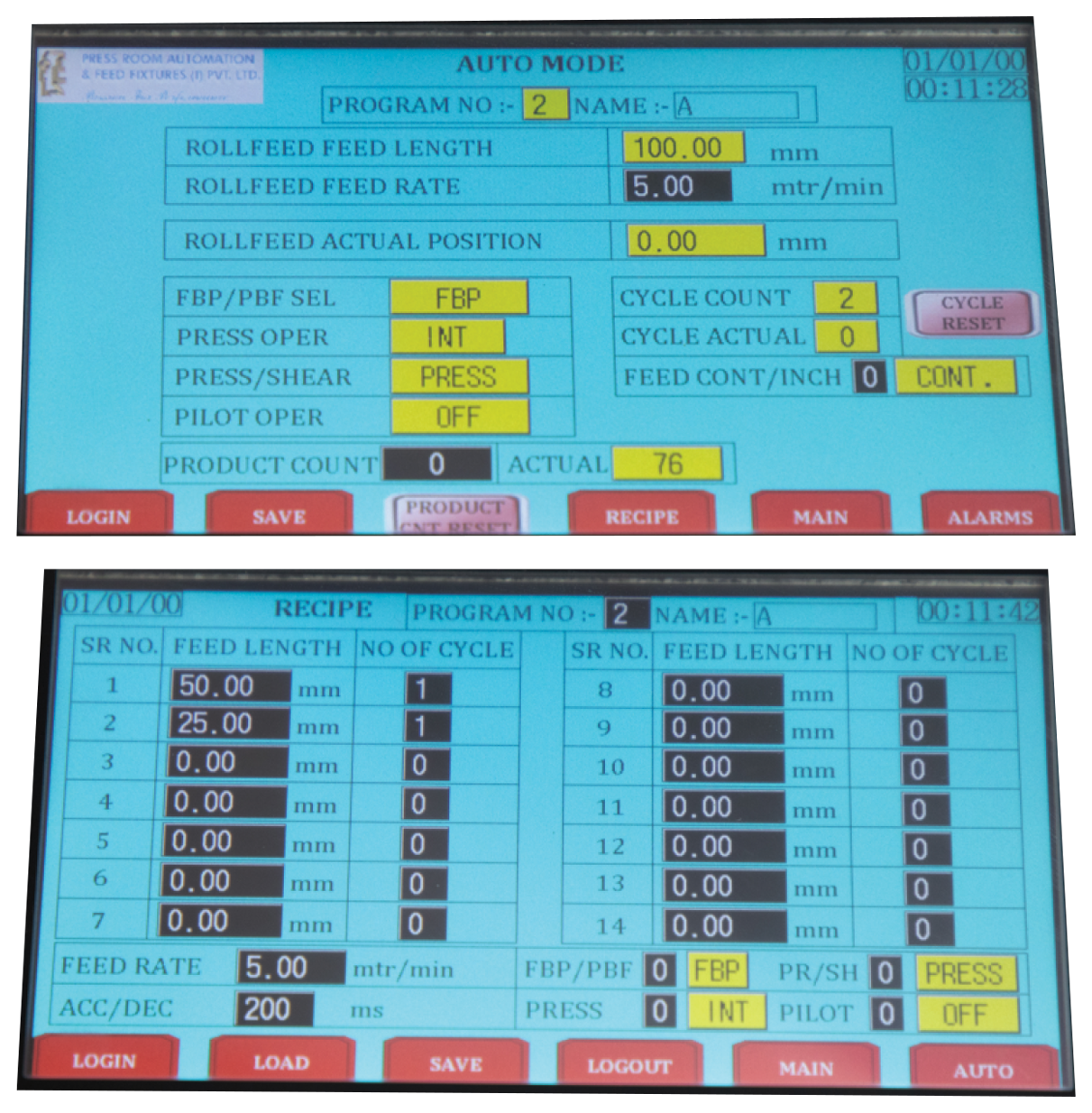

- • Operator panel with the possibility to program 99 programs of 14 different steps repeat no. of times.

- • Programmable feed length from 1 mm to 9999 mm.

- • Feed accuracy 0.04 mm.

- • Measuring wheel with encoder

- • Program to give signal to shear after feeding sequence is completed for cutting material at required length.

- • OPTIONAL : Synchro with press by absolute encoder mounted on the press main shaft.

- • Special Mitsubishi Servo Motor With 41,94,304 pulses is used on Measuring Wheel. It detects the length and position of the strip and sends the signal to Servo Motor Resolver resulting in accurate pitch length.

- • Imported Gearbox coupled with Rigid MAV coupling is used. It avoids backlash which is normally associated with timer belt feeder.

Mechanical Features

- • Minimum Backlash Gearbox is used for better accuracy & higher torque.

- • The accuracy is made by a double measuring system servo motor resolver + measuring wheel on sheet.

- • We use special 41,94,304 pulsed Mitsubishi Servo Motor instead of lesser pulsed encoder.

- • Transmission of power from lower shaft to upper shaft servo feeder is through 4 hardened and ground gears housed in 4 TDC plates.

- • Results in min backlash during too / fro motion.

- • Pass line adjustment as per tool feeding height is set automatically.

- • Exit roller guide when used along with entry width guide (4 Rollers ) feeds material perfectly straight.

- • Inlet Bracket allows smooth flow of material inside feeder.

- • 4 roller guide in entry width guide results in material being feed perfectly straight & centered.

Sequential Length Feeding

Sequential Length setting for different feeding lengths. We have 14 nos. sequence which can be programmed.

Shear Actuation Program

After set cycles of feeding lengths have been completed, a signal to solenoid valve is given to actuate standalone shear or in die pneumatic cylinder. Material is cut at required length and cycle restarts. A Press Permit signal is given to the stop the press when shearing of material is taking place.

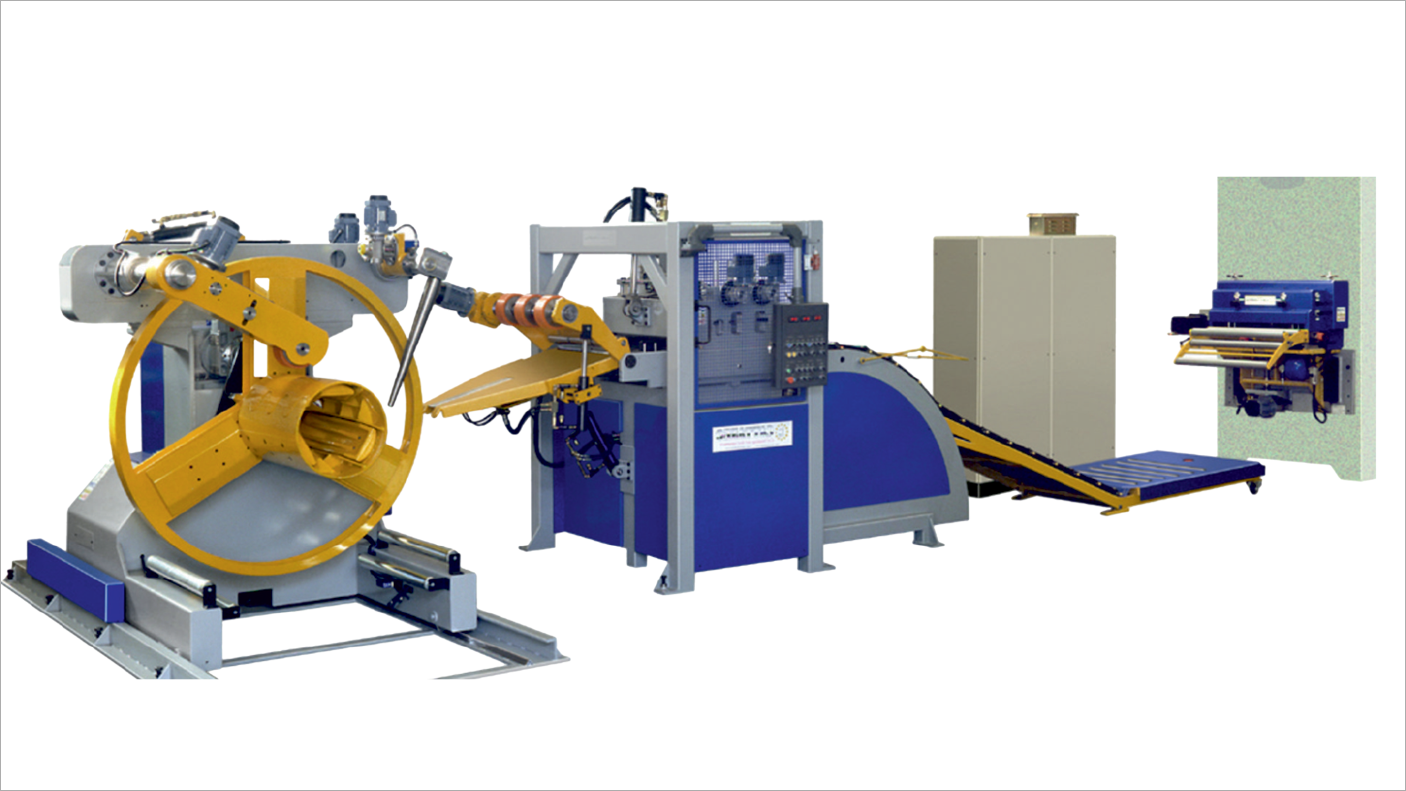

High Precision NC Servo Feeder (Standard Models)

| Model | Strip Width (mm) | Max Strip Thickness (mm) | Roll ø (mm) | Max Speed (m/mm) |

|---|---|---|---|---|

| SRF 80 | 150 | 3 | 80 | 96 |

| 200 | 3 | 80 | 96 | |

| SRF 100 | 200 | 4 | 100 | 93 |

| 300 | 4 | 100 | 93 | |

| 400 | 3.5 | 100 | 93 | |

| SRF 120 | 600 | 8 | 120 | 61 |

| 800 | 7 | 120 | 61 | |

| SRF 160 | 800 | 8 | 160 | 81 |

| 1300 | 7 | 160 | 81 |

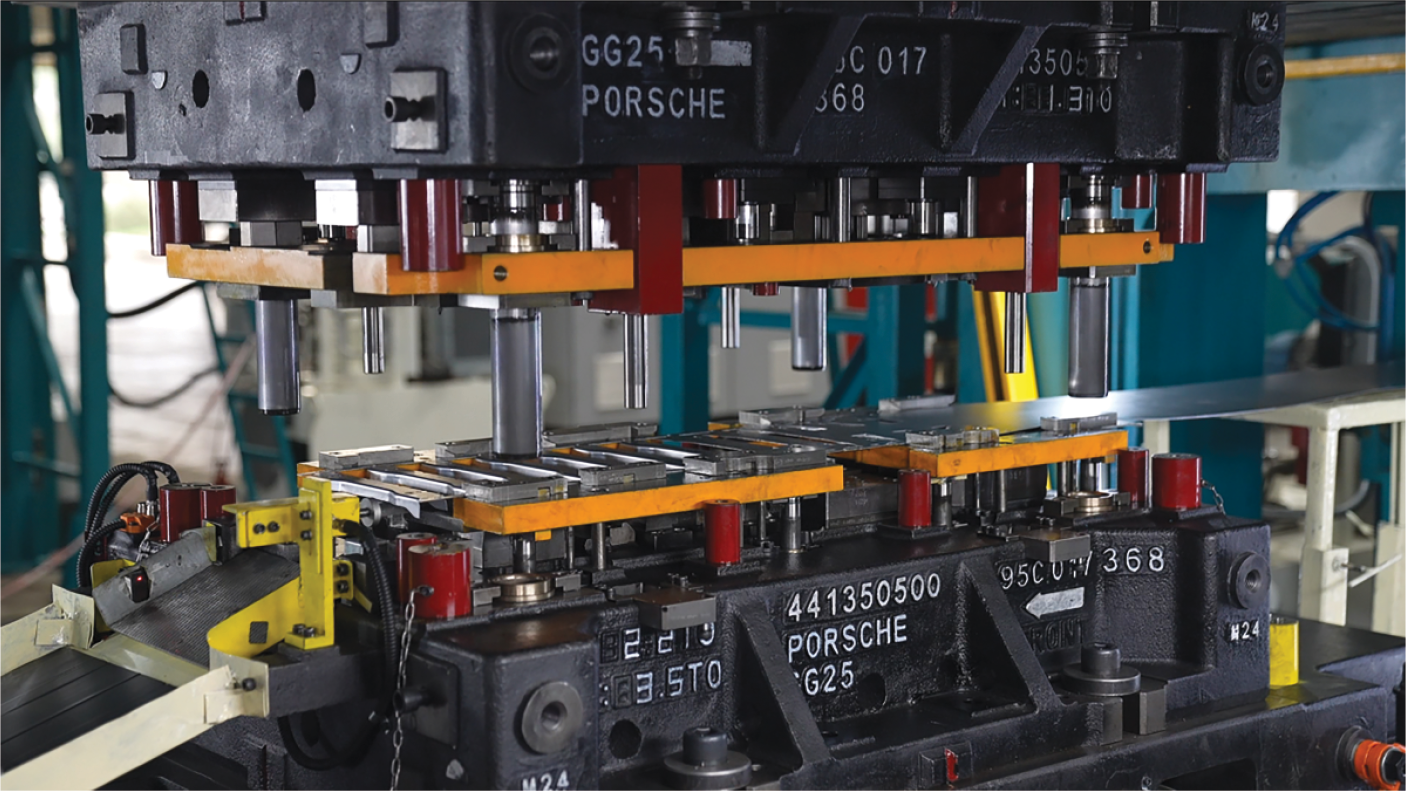

NC Servo Feeder with Multi Punch, Higher End NC Servo Roll Feeder