PRESS ROOM AUTOMATION cut-to-length lines are sheet metal forming lines for strip material. The strip material is transferred from the coil, levelled, cut-to-length and stacked. By combining components according to our customers' specific production requirements we design customized lines that provide optimum production capacity. All functions can be controlled centrally and, if required, entered or controlled via monitor.

Cut-to-length lines are designed and built according to your special requirements. Based on our customers' input, a team of highly-qualifiedPRESS ROOM AUTOMATIONemployees develops and designs a line concept that offers the most economical solution while achieving an increase in production and a higher product quality.

Standard Features

Specifications:

Transformer Lamination Punching, Notching & Variable CTL

PRESS ROOM AUTOMATION manufacturers high speed cut to length line uptill 400 mm for Transformer Lamination with Punching, Notching & Variable CTL. Typically line consists of Decoiler, NC Servo Feeder, Puching or Notching or both stations, Servo Shear, Stacker.

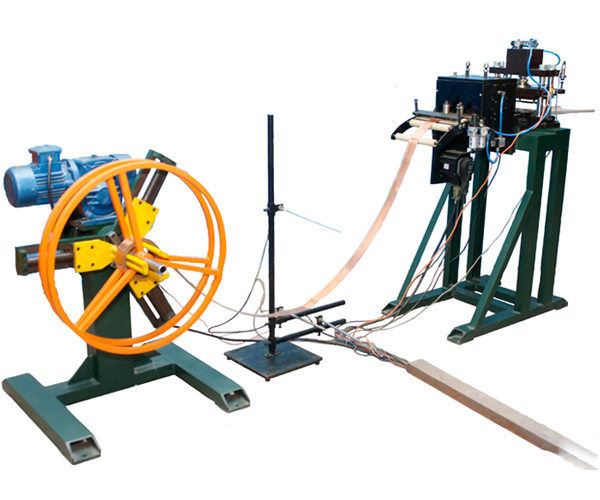

Cut to Length Line for Copper Flexible Connector

PRESS ROOM AUTOMATION manufacturers Cut to Length Line for Copper Flexible Connector. Typically line consists of Decoiler, NC Servo Feeder & Pneumatic Shear.

Special Features of Line:

Normal Speed Model

|

For Narrow Width |

For High Speed Narrow Width |

For Wider Width |

Width |

0-400 mm |

0-400 mm |

400-1500 mm |

Thickness Range |

0.1-4.0 mm |

0.1-0.8 mm |

0.5-3.0 mm |

Line Speed |

10-20 MPM |

20-40 MPM |

40-60 MPM |

Coil Weight |

Upto 2.5 Tonne |

Upto 2.5 Tonne |

Upto 10 Tonne |

Technical specifications are indicative and subject to change to suit end application.

Cut to Length Line for wire feeding with Pneumatic Decoiler, Wire Straightener

Cut to Length for Aluminium, Cut to Length for Aluminium

Cut to Length Line, Cut to Length Line Manufacturer, Cut to Length Line

Cut to Length Line with Decoiler, Pneumatic Feeder and Hydro Pneumatic Shear

Copper Cut to Length Line, Copper Cut to Length Line

Cut To Length Line consisting of Compact Type Decoiler Cum Straightener

Cut to Length Line with Moterised Decoiler & NC Servo Roll Feeder

Cut To Length Line consisting of Compact Type Decoiler Cum Straightener & Pneumatic Feeder e

Heavy Cut to Length Line for GI Material with Coil Car, Decoiler, Precision Straightener

Cut to Length Line consisting Decoiler cum Straightener, NC Servo Roll Feeder