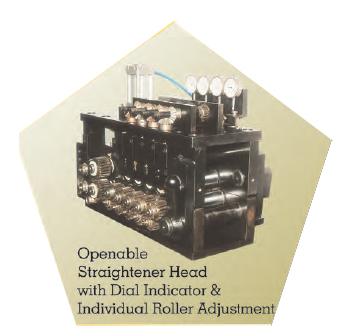

FEATURES

OPTIONS

Motorised Coil Straightener ( Standard Models ) |

|||||||

Model |

Max. |

Thickness |

Roll |

No. Of |

Power |

Centre Height |

Occup. Area ( mm ) |

S-200-25-13 |

200 |

0.35 TO 0.8 |

25 |

13 |

2 |

1100 |

900×530×1265 |

S-150-32-9 |

150 |

0.35 TO 1.2 |

32 |

9 |

1.5 |

985 |

770 × 625 × 1150 |

S-200-40-9 |

200 |

0.4 TO 1.8 |

40 |

9 |

1.5 |

1115 |

790 × 625 × 1380 |

S-150-50-9 |

150 |

0.5 TO 3.0 |

50 |

9 |

1.5 |

915 |

840 × 575 × 1350 |

S-200-65-7 |

200 |

0.7 TO 4.0 |

65 |

7 |

2 |

1200 |

850 × 580 × 1400 |

S-300-65-7 |

300 |

0.7 TO 3.0 |

65 |

7 |

2 |

1200 |

850 × 680 × 1400 |

S-400-65-7 |

400 |

0.7 TO 2.2 |

65 |

7 |

2 |

1200 |

850 × 780 × 1400 |

S-500-65-7 |

500 | 0.7 TO 1.8 |

65 |

7 | 2 | 1200 | 850 × 880 × 1400 |

S-600-65-7 |

600 | 0.7 TO 1.5 |

65 |

7 | 2 | 1200 | 850 × 980 × 1400 |

S-300-80-7 |

300 | 0.8 to 5.0 | 80 | 7 | 3 | 1340 | 1200 × 800 × 1220 |

S-400-80-7 |

400 | 0.8 to 4.0 | 80 | 7 | 3 | 1340 | 1200 × 900 × 1220 |

S-500-80-7 |

500 | 0.8 to 3.5 | 80 | 7 | 3 | 1340 | 1200 × 1000 × 1220 |

S-600-80-7 |

600 | 0.8 to 3.0 | 80 | 7 | 3 | 1340 | 1200 ×1100 × 1220 |

S-400-90-7 |

400 | 0.9 to 5.0 | 90 | 7 | 5 | 1395 | 1295 × 950 × 1440 |

S-500-90-7 |

500 | 1 to 4.5 | 90 | 7 | 5 | 1395 | 1295 ×1050 × 1440 |

S-600-90-7 |

600 | 1 to 4.0 | 90 | 7 | 5 | 1395 | 1295 × 1150 × 1440 |

All above equipments are designed for Line speed of 12-15 Mtrs. Per Minute.

Models of higher capacity or Higher or Lower Line speeds are available on request.

Technical specifications are indicative and subject to change to suit end application.