JSM PART CONVEYOR

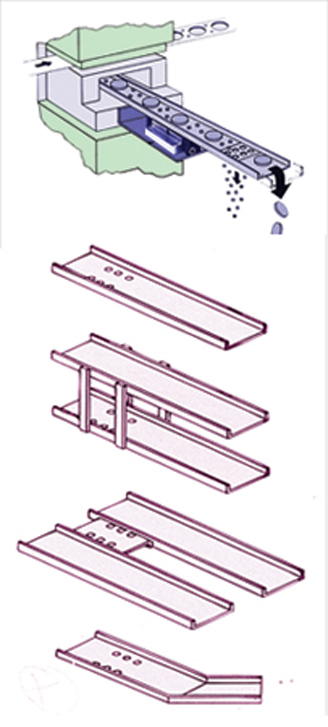

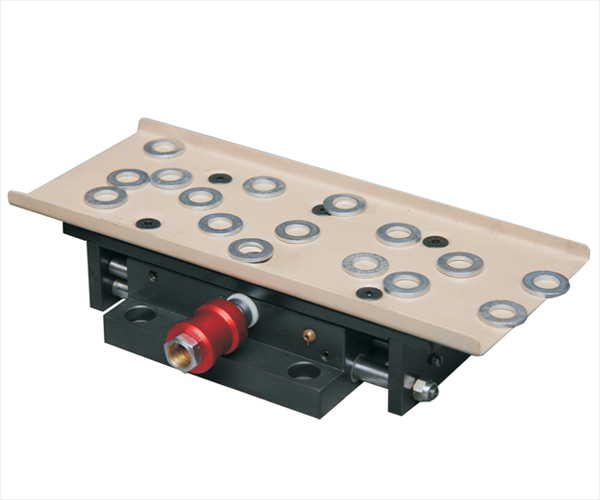

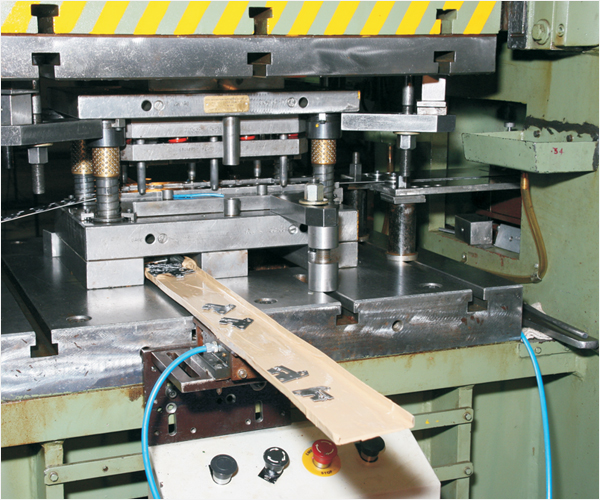

JSM Part Conveyors are simple, compact, modular, accurate reliable pneumatic gadget to remove components, sligs, shaving, pinching scrap from the bottom of the Die.They are beltless conveyors and they transport the pieces with a shaking tray motion. A part customised tray fixed on the standard body with to & fro motion. The linear motion moves tray slowly forward and then quickly backwards. This motion pushes the components & scrap outside Die area into container.

Though it operates on compressed air, the consumption of air is very low and they cost very less compared to

A. Compared to manual unloading it has following advantages

1. Safe operations

2. Die and operator safety

3. Elimination of operator fatigue for removing parts.

4. Systematic separational of parts and scraps

5. Elimanation of sorting of parts/scrap

6. Eliminated additional manpower

7. Pay - back period is less then 1 year

B. Compared to motorised conveyors, it has following advantages

Replacement cost of belts, conveyors, bearings, justifies this low cost part Transporter on the conventional belt conveyors.

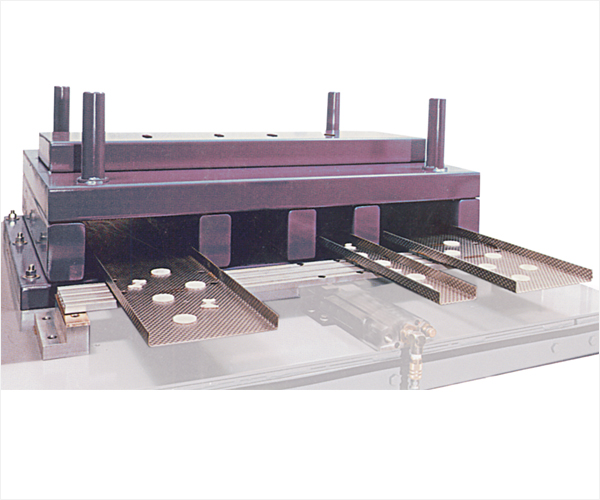

It separates each element scrap, part and in larger models two or more customised traya can be used to separate each element coming out from punching. This saves additional investment cost. Two/Three trays in parallel or one above another can separate the element for most cleaner operation.

When to use

There are four major areas where the JSM Part Transporter will outperfrom a conveyor.

Additional Application

Today Part Transporter is replacing conventional belt conveyor in assembly type operations to move parts.

Normal Speed Model

| S P E C I F I C A T I O N S | |||||||

Model |

Load Capacity |

Line Speed (MPM) |

Air Consumption (CEM) |

Stroke Lenght |

Max.Tray Weight Kg |

Air Pressure Range (PSI) |

Max.Incline of Tray |

| JSM PC-1 | 3 |

7-10 |

0.5 |

20 |

1.5 |

50-75 |

8° |

| JSM PC-2 | 10 |

7-10 |

0.7 |

20 |

3.0 |

50-75 |

8° |

| JSM PC-3 | 20 |

7-10 |

1.4 |

25 |

10.0 |

50-75 |

8° |

Technical specifications are indicative and subject to change to suit end application.

We are Part Conveyor PC 1, Part Conveyor PC 1 Manufacturer, Part Conveyor PC 1 Supplier

Part Conveyor, Part Conveyor Manufacturer, Part Conveyor Supplier

CRADLE+SERVO FEEDER+PART CONVEYOR

Part Conveyor PC 3, Part Conveyor PC 3 Manufacturer, Part Conveyor PC 3