Press Room Automation was the first Indian manufacturer to recognize the potential of the new technology of servo-driven press feeding equipment (NC Servo Feeder) in 2001. Press Room Automation has redesigned and simplified its entire Servo Roll Feeder line, employing innovative, new manufacturing techniques to bring you the highest quality, lowest maintenance, most economical servo line ever.

Servo-driven feed rolls grip and move material rapidly and precisely into a stamping press or automation operation. Press Room Automation includes user-friendly features at no extra charge—quick-release handles to adjust roller stock guides, exit support and stock buckle bridge, transition mounting brackets, positive pilot release, and roll release for material insertion via pneumatic cylinder are just a few of our standard features. All Press Room Automation Servo Roll Feeder models have extra-large rolls to withstand the toughest abuse and harshest pressroom environments. Compare our rated specifications and generous roll diameter against any other feed builder.

Features

ADDITIONAL FEATURES

ACCESSORIES & OPTIONS

| Extra Light Series (ELS) | ||||||

| Models | Max Width in mm | Thickness Range in mm |

Max Thickness with Max Width in mm |

Max Section in mm2 | Max Velocity in MPM |

|

| Min | Max. | |||||

| PRSF-AA-200-ELS | 200 | 0.1 | 2.0 | 1.5 | 300 | 90 |

| PRSF-AA-300-ELS | 300 | 1.5 | 1.0 | 300 | 90 | |

| Light Series (LS) | ||||||

| Models | Max Width in mm | Thickness Range in mm |

Max Thickness with Max Width in mm |

Max Section in mm2 | Max Velocity in MPM |

|

| Min | Max. | |||||

| PRSF-A-200-LS | 200 | 0.1 | 3.0 | 3.0 | 400 | 90 |

| PRSF-A-300-LS | 300 | 1.6 | 480 | 90 | ||

| PRSF-A-400-LS | 400 | 1.2 | 480 | 90 | ||

| MID Series (MS) | ||||||

| Models | Max Width in mm | Thickness Range in mm |

Max Thickness with Max Width in mm |

Max Section in mm2 | Max Velocity in MPM |

|

| Min | Max. | |||||

| PRSF-B-200-MS | 200 | 0.3 | 3.5 | 3.0 | 600 | 90 |

| PRSF-B-300-MS | 300 | 2.5 | 750 | 90 | ||

| PRSF-B-400-MS | 400 | 2.0 | 800 | 90 | ||

| PRSF-B-600-MS | 600 | 0.3 | 2.5 | 2.5 | 1500 | 90 |

| PRSF-B-800-MS | 800 | 1.6 | 1280 | 90 | ||

| PRSF-B-1000-MS | 1000 | 1.4 | 1400 | 90 | ||

| Extra MID Series (EMS) | ||||||

| Models | Max Width in mm | Thickness Range in mm |

Max Thickness with Max Width in mm |

Max Section in mm2 | Max Velocity in MPM |

|

| Min | Max. | |||||

| PRSF-BH-300-EMS | 300 | 0.3 | 4.0 | 4.0 | 1200 | 90 |

| PRSF-BH-400-EMS | 400 | 3.0 | 1200 | 90 | ||

| Heavy Series (HS) | ||||||

| Models | Max Width in mm | Thickness Range in mm |

Max Thickness with Max Width in mm |

Max Section in mm2 | Max Velocity in MPM |

|

| Min | Max. | |||||

| PRSF-CH-300-HS | 300 | 0.5 | 6.0 | 6.0 | 1800 | 90 |

| PRSF-CH-400-HS | 400 | 5.0 | 2000 | 90 | ||

| PRSF-CH-500-HS | 500 | 4.8 | 2400 | 90 | ||

| PRSF-CH-600-HS | 600 | 4.0 | 2400 | 90 | ||

| PRSF-CH-800-HS | 800 | 3.0 | 2400 | 90 | ||

| PRSF-CH-1000-HS | 1000 | 2.0 | 2000 | 90 | ||

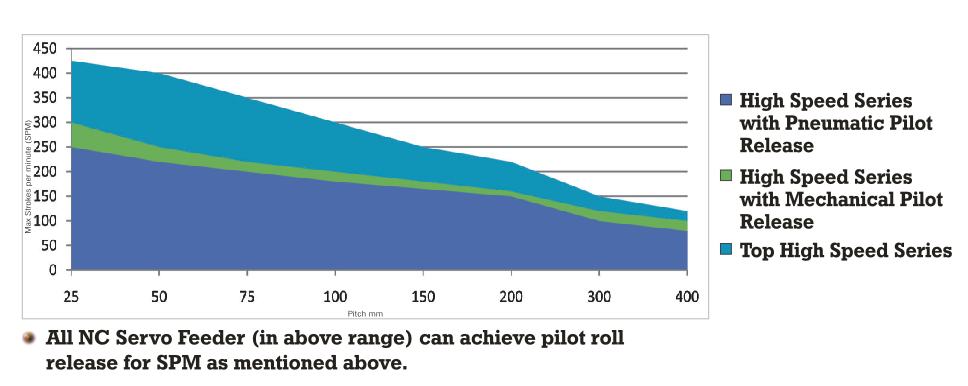

High Speed Series with Pneumatic Pilot Release

High Speed Series with Pneumatic Pilot Release High Speed Series with Pneumatic Pilot release mechanism is suitable for electrical motor stamping & electrical lamination mfg. industries. Special high frequency & high flow solonoid valves are using to achive pilot release at high speed of 24 to 30 mpm.

| High Speed Series | |||

| Models | Max Width in mm | Max Thickness Range in mm |

Max Velocity in mm |

| PRSF-A-200-HSS | 200 | 0.1-1.0 | 120 |

| PRSF-A-300-HSS | 300 | 0.1-1.0 | 120 |

| PRSF-A-400-HSS | 400 | 0.1-0.8 | 120 |

High Speed Series with Mechanical Pilot Release

High Speed Series with Mechanical Pilot release is suitable for electrical motor stamping & electrical lamination mfg. industries where line speed is uptil 40 mpm.

| High Speed Series with Mechanical Pilot Release | |||

| Models | Max Width in mm | Max Thickness Range in mm |

Max Velocity in mm |

| PRSF-B-200-HSS | 200 | 0.1-1.0 | 120 |

| PRSF-B-300-HSS | 300 | 0.1-1.0 | 120 |

| PRSF-B-400-HSS | 400 | 0.1-0.8 | 120 |

Top High Speed Series

In top High Speed Series, Feed and Pilot release are done by two separate servo motors. This enable to achieve desired line speed uptill 60 mpm with high accuracy.

| Top High Speed Series | |||

| Models | Max Width in mm | Max Thickness Range in mm |

Max Velocity in mm |

| PRSF-B-200-HSS | 200 | 0.1-1.0 | 200 |

| PRSF-B-300-HSS | 300 | 0.1-1.0 | 200 |

| PRSF-B-400-HSS | 400 | 0.1-0.8 | 200 |

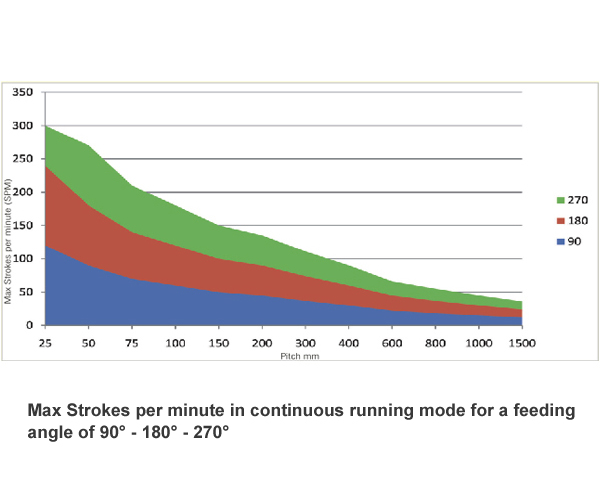

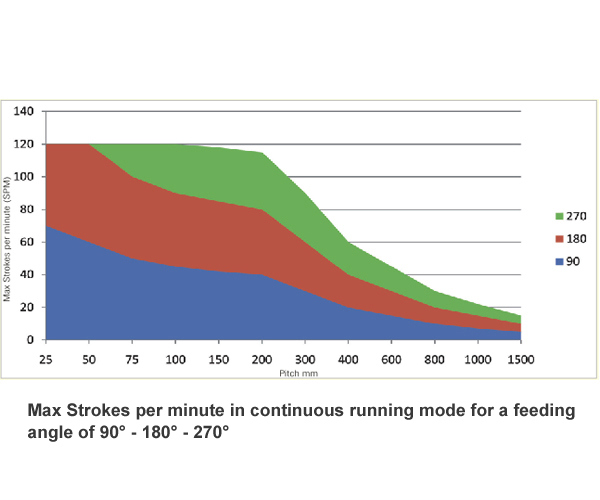

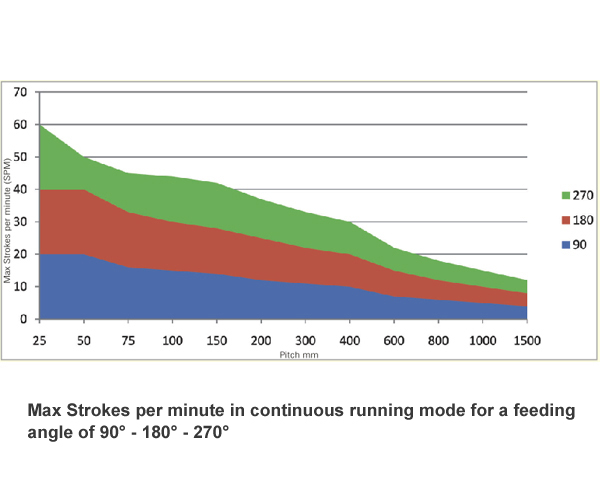

High Speed Series Fedding Rates

Max Stokes per minute in continuous running mode for a feeding angle of 180°

Feeders For Different Applications

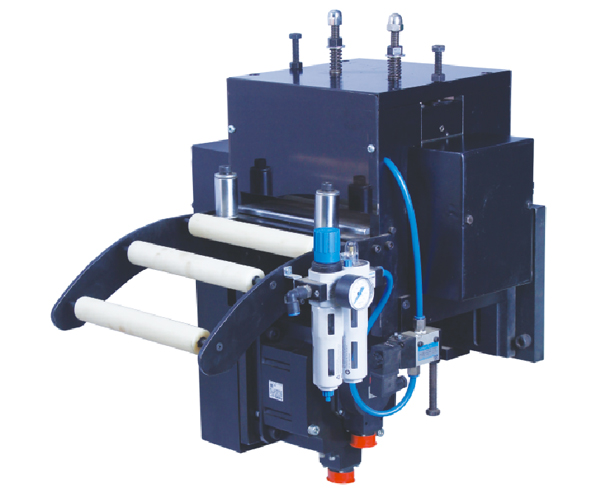

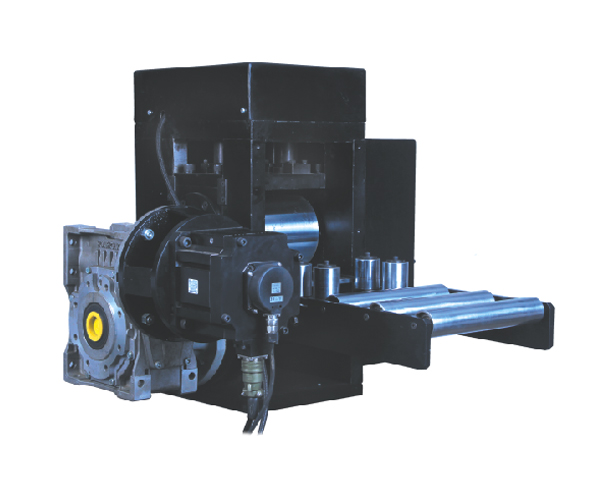

FOR COPPER MATERIAL COMPACT + NC SERVO ROLL FEEDER

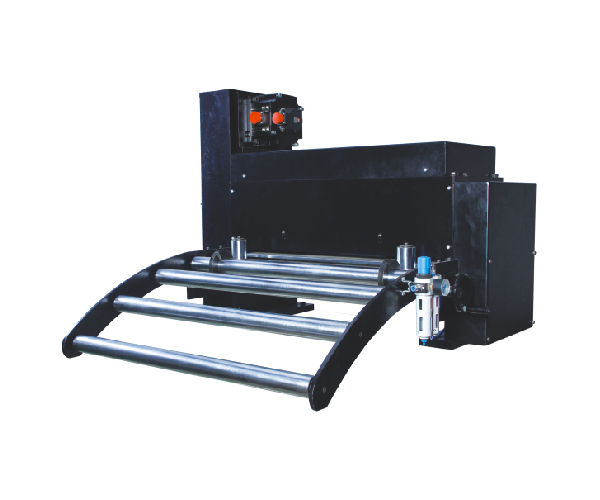

FOR COPPER MATERIAL DECOILER + NC SERVO ROLL FEEDER

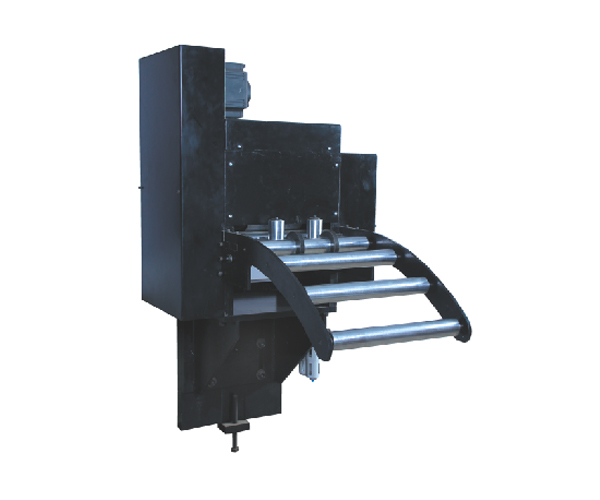

Press Feeding Line with Twin Decoiler, Straightner, NC Servo Roll Feeder & Recoiler for Circlip Manu

Press Feeding Line with NC Servo Roll Feeder for Tandom Presses